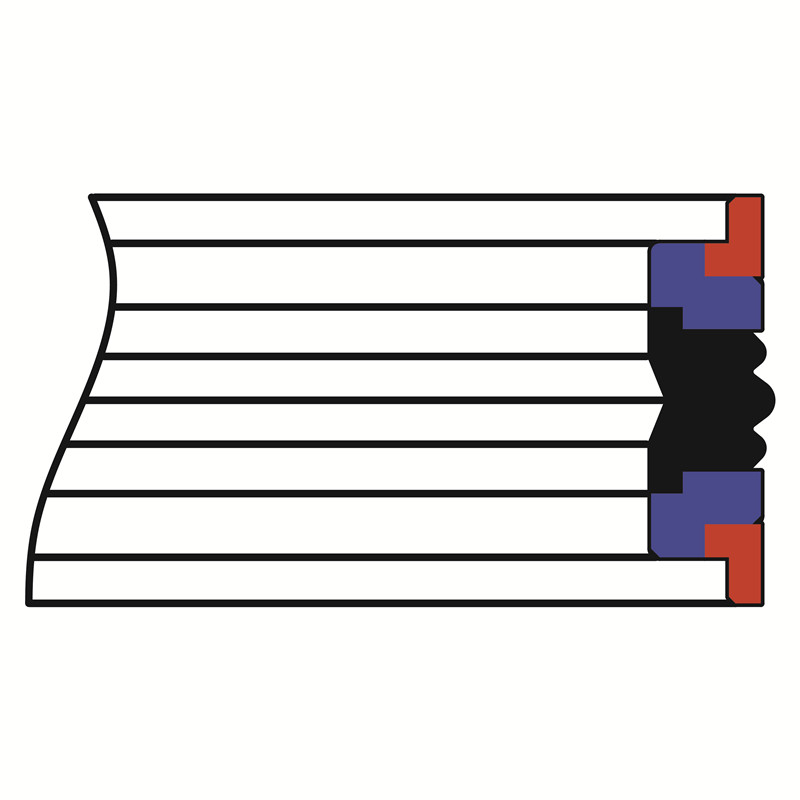

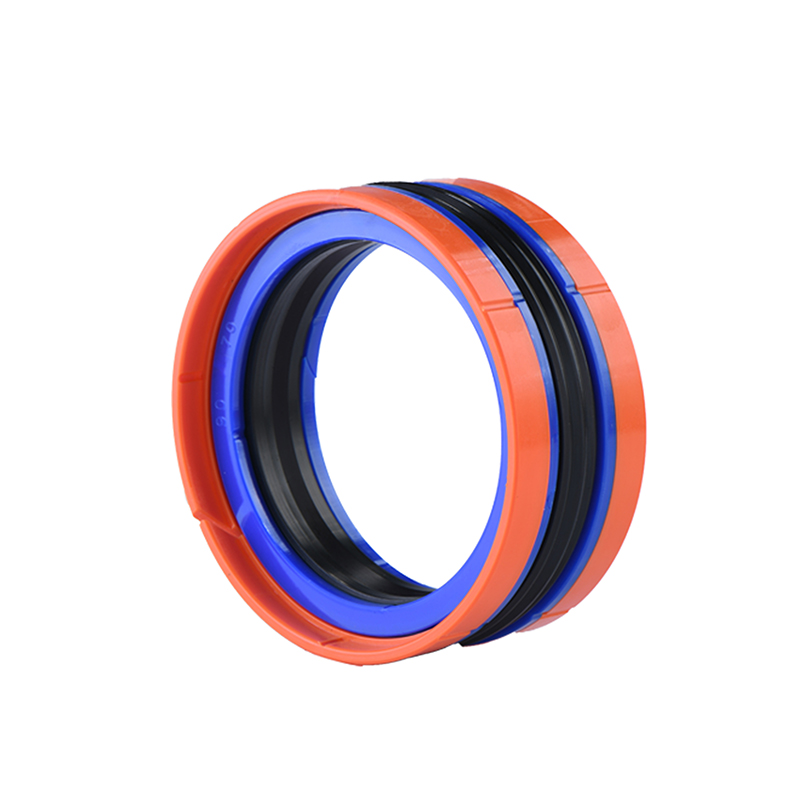

Hydraulic five-combination seals are commonly used for piston sealing in hydraulic cylinders. They typically consist of the following five components:

One elastic rubber main sealing ring (usually made of NBR or FKM)

Two back-up rings

Two guide rings or retaining rings

Within this type of seal structure, KDAS and DPM refer to two different types or standards. The main differences lie in their design, material composition, and application performance.

Structure Features:

A classic five-piece combination seal

Contains a rubber sealing ring in the middle, with two guide rings (usually made of POM) on either side, along with two back-up rings

The back-up rings prevent rubber extrusion under high pressure, and the guide rings provide alignment and structural support

Typical Applications:

Medium to high-pressure hydraulic systems

Commonly used for piston sealing in single or double-acting cylinders

Suitable for heavy-load and repetitive motion environments

Advantages:

Easy to install

Stable sealing performance, high-pressure resistance, strong anti-extrusion capacity

DPM Seal

Structure Features:

Also typically a five-piece combination, but the design differs slightly from KDAS

"DPM" is often a model name used by specific manufacturers (e.g., Merkel, Parker)

The seal structure may be more compact, with variations in the material and dimensions of the guide and back-up rings

Typical Applications:

Suitable for more specific or demanding conditions (e.g., high-frequency reciprocating motion or ultra-high-pressure systems)

Some DPM versions are capable of bi-directional sealing (for double-acting cylinders)

Advantages:

Customizable geometries for different installation needs (e.g., shallow grooves)

Better suited for space-constrained or high-pressure, high-speed environments

Comparison Table:

FeatureKDASDPM

Structure Standard five-piece configuration Customizable; more design variants

Material NBR/FKM + POM/PA rings Varies by manufacture

Post time: Jul-03-2025